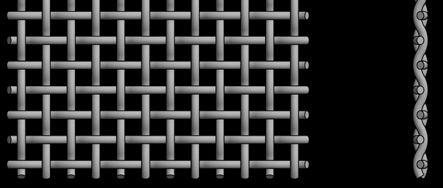

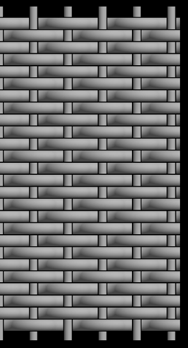

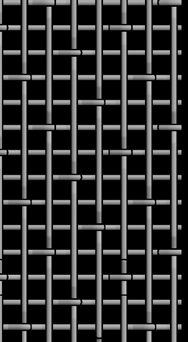

Plain Weave

The simplest and most commonly used type with square openings. It is woven by alternating the weft wire over and under the warp wire and permits positive control of size of materials to be screened or filtered.

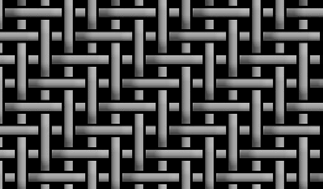

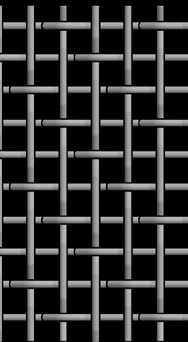

Twill Weave

Each weft wire passes alternately over and under 2 warp wires, staggered on successive warps. It is used where fine mesh must carry a heavy load.

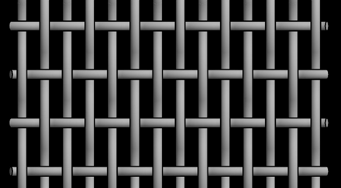

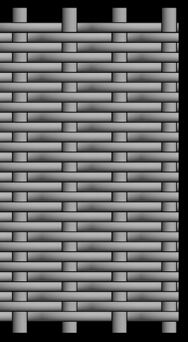

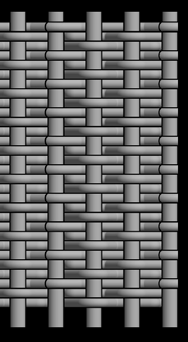

Oblong Weave

Also known as broad weave, it is made preferably in plain weave with an opening ratio (length/width) of 3:1. Other ratios are possible. Triple warp weave is also available to provide large open areas. It is used for vibrating sieving screens or other architectural applications.

Plain Dutch Weave

This simple dutch weave is the most common filter cloth. Generally, the diameter of warp wire is larger than the weft wire. Warp and weft wires are interwoven closely together at set intervals. It is ideally suited for filtration applications, as well as the separation of slurry and liquid materials.

Twill Dutch Weave

This weave type offers a significant upgrade in strength over plain dutch weave wire cloth. It actually combines the Dutch and twill weaving process to produce an extremely fine mesh filtering cloth that is created by passing weft wires over and under two warp wires. As a result, it is suitable for various liquid and gas filtration applications.

Reverse Dutch Weave

This weave type is in a reverse of the plain dutch weave wire arrangement. The diameter of warp wire is smaller than the weft wire. Warp and weft wires are interwoven closely together at set intervals. It is well-suited for high pressure vertical and horizontal filter leaf applications where backwashing and filter cake removal are important.

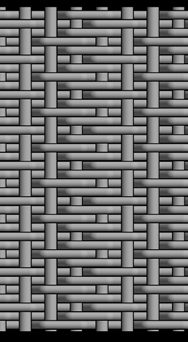

3-Heddle Weave

In this weave type, every warp wire alternately passes up and down each one and two weft wires alternately. Similarly, each weft wire goes alternately up and down of each and two warp wires. It is widely used in industry filters, filter discs and filter cylinders for filtration.

5-Heddle Weave

In this weave type, every warp wire alternately up and down each single and four weft wires and vice versa. It provides a rectangular opening and offers high flow rates. It is widely used in filtration of petroleum & chemical industries.

3-Heddle Twill Dutch Weave

Similar like 3-heddle weave, this type of weave has a larger diameter of warp wire than the weft wire. Besides, weft wires are closely arranged, leaving no gaps between weft wires. As a result, it is suitable for filtration applications that require high filtration accuracy and heavy load bearing capacity.

Pre: The advantage of rapier loom to shuttle loom

Next:Construction & Mining Indonesia